Heat transfer paper only has two main kinds: inkjet and laser transfer paper. They are specific and designed to switch the printing processes with their particular copier type. An inkjet printer uses inkjet paper.

This paper is intended to be used with inkjet printers only. Whereas, laser paper is specialized to grip heat and toner elements.

Apart from these two types, sublimation is another form of heat transfer printing. So we’ll also study all the types of heat transfer paper today and let you know how you can use them.

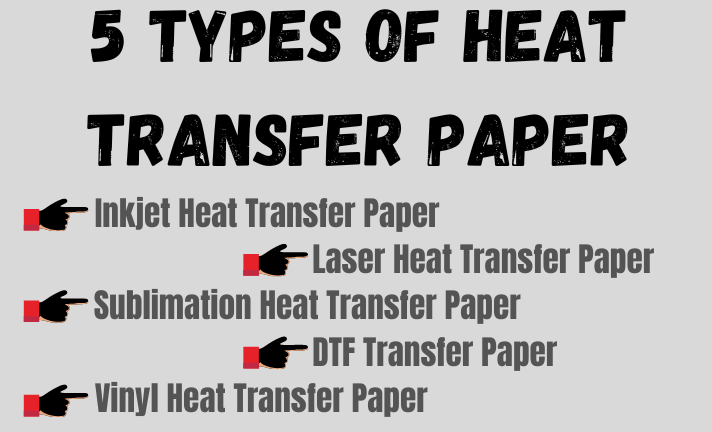

5 Types of Heat Transfer Paper

Different types of heat transfer paper are available in the market. Each type suits different printing methods and fabric types. You should know the features of each paper type to achieve the best results.

Here is the contrast table. It shows the key differences between inkjet and laser heat transfer papers.

1. Inkjet Heat Transfer Paper

Inkjet paper is specialized and bound to be used with only inkjet printers. The film is clear. It is then transferred onto a heat-sub sheet. Later, the design is transferred onto the t-shirt. Another type of inkjet paper comes in a white base.

It is coated with either wax or aqueous colloid resin. The coating has a preferable amount of viscosity, which binds the ink. This prevents smudging and ensures vibrant colors.

Inkjet transfer paper looks transparent. The translucent coating on the heat-sub-transfer paper ensures the proper transfer of ink particles. It transfers them onto the surface of the substrate or fabric.

Recommended applications and fabric types

Light-colored textiles perform well with inkjet heat transfer paper. These include cotton or polyester. It also works well with any mixed fabric type. It provides excellent image resolution and details. But, there are always exceptions.

You cannot apply heat to viscose or pure rayon. They contain heat-sensitive elements.

But, you cannot use transparent inkjet heat transfer paper for dark color garments. When using inkjet heat transfer paper on dark clothes, use a type of heat transfer paper with a white backing. This white backing allows the print to show up on the dark garment.

2. Laser Heat Transfer Paper

Laser heat transfer paper is designed for laser printers. This is because laser printers use heat to melt the toner. Laser heat transfer paper is heat-unaffected. It fuses the toner subdivisions onto the fabric when heat is applied.

Laser heat transfer paper also has a heat-activated coating. It bonds the image to the fabric. Yet laser heat transfer paper is grey colored not translucent.

3. Sublimation Heat Transfer Paper

Heat transfer paper is not the same as sublimation transfer paper. Additionally, a polyester layer is used to bind the sublimation ink. The sublimation paper enables the transfer of designs onto polyester or polyester-coated substrates. In heat transfer paper printing, ink doesn’t fill the t-shirt pores. But with sublimation ink heat presses ink into the t-shirt pores.

Sublimation heat transfer paper is sturdier and more permanent. It resists peeling and fading. The biggest restriction in sublimation transfer paper printing is that you cannot sublimate dark colors. Dark colors are also restricted.

You need to take more steps. And even it won’t be possible to sublimate on cotton because cotton fabric pores are not being unlocked during heat press.

Various ways allow you to sublimate dark or black color and cotton. With the following steps, you can sublimate both of them too.

4. DTF Transfer Paper

DTF process is thriving in the printing market. But, it is more complex than sublimation and heat transfer paper. The DFT transfer process uses a PET film. It’s also referred to as DTF film.

First, a design is printed on DTF film using a DTF printer. Then, a white ink layer is printed over the image. The double-printed DTF film is then coated with wet DTF powder that sticks to the ink.

After that, the DTF film is cured using a heat press or a curing oven to get the adhesive powder packed with the film. The DTF film is now prepared to be applied to the t-shirt. It can go on yarn, polyester, or dark and light-color garments.

5. Vinyl Heat Transfer Paper

Vinyl heat transfer paper (HTV) is made from plastisol vinyl. It’s also called iron-on vinyl paper. It has an adhesive backing, and you can print on the vinyl. Heat transfer vinyl is also used to create designs on t-shirts and apparel. It procedures a layer of vinyl over the t-shirt in coatings.

Vinyl heat handover requires a vinyl plotter to cut the design. Use a weeding tool to remove the vinyl parts that have already been cut. Heat transfer vinyl comes in different textures, such as sleek or glittery, colors. It can be applied to shirts of any color and material.

Image Quality and Durability Considering

Image quality and durability are one of the crucial aspects that are must be considered. Heat transfer paper sublimation is one of the most robust printing techniques. It doesn’t fade or peel as easily. The heat transfer paper printing way is versatile. It has no limits on color and garment type.

Choosing the ideal printer for heat transfer t-shirts is essential. This will ensure you get the desired, high-quality results.

• For improved clarity and detail, use a better printer with high resolution.

Mirror the design before lithography in all transfer methods. This is especially important for text or logos. It ensures correct orientation upon transferring the design.

· The printer settings can be conversant for using the right paper type.

Apply firm and even pressure during the allocation process. This will keep the design from feeling off after laundry.

FAQS

Can we apply heat transfer paper to materials other than textiles?

Yes, heat transfers daily. It can also decorate mugs, ceramics, wood, metal, or plastic. But, checking the heat delivery paper’s instructions is recommended, if any. This ensures compatibility with other surfaces.

Can I reuse heat transfer paper?

No! Heat transfer paper is considered for one-time use. The coated layer on the paper is activated once the heat transfer paper has been utilized. It moves with the ink during heat tenacity. So if reuse is used, the final fallouts may be poor or faded with a single wash.

Conclusion

We’ve described the 5 types of heat transfer daily. These are used to customize clothing and other kinds of substrates. Finally, the top printing paper and method depend on your printing needs. They will also depend on the fabric you tend to customize.

Each letterpress paper has its effects that make them distinct from each other. So go ahead and explore the various types of heat transfer paper. Unleash your ingenuity in wily, unique, and bespoke creations.

For More Visit: printerguidepro.com

Posted In: Heat Transfer

Related Post: Regular Ink Is Used on Heat Transfer Paper?

Best Regards: { Rayyan Haider }